Manufacturing Capabilities for Custom PCB Requirements

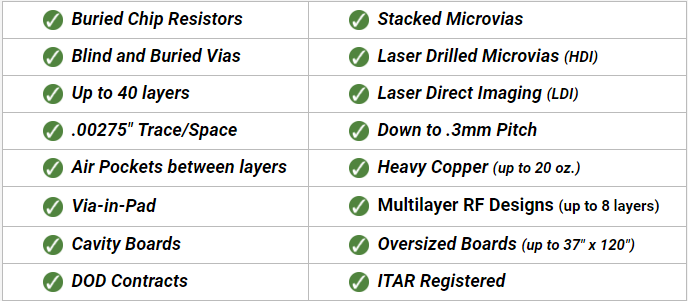

AdvancedPCB leads the North American printed circuit board industry in quality and innovation by providing full-service PCB fabrication to meet the most rigorous custom PCB requirements. Our PCB manufacturing capabilities range from simple PCB prototypes to advanced PCBs with tight tolerances, high layer count (up to 40 layers), heavy copper (up to 20 oz.), and more.

PCB Capabilities→Advanced Materials for Custom PCB Fabrication

Depending on the product application for which a custom PCB is being designed for, advanced laminate materials may be required. AdvancedPCB sources a broad range of PCB laminate materials to meet your specifications from leading providers such as 3M, Arlon, Rogers, Ventec, Isola, and Bergquist to name a few. Our custom PCB material options include:

- RoHS Compliant

- Halogen Free

- RF Materials

- Advanced RF Materials

- Advanced HDI

- Advanced Signal Integrity

Custom PCB Plating Finish Options

The plating finish applied to a printed circuit board consists of metal deposited to the exposed copper and plated thru holes in a chemical process. Custom PCB design engineers are able to specify the surface finish required after carefully considering cost, shelf life, solder rework capabilities, solder wettability, solder joint integrity, RoHS compliance, and any other attributes the different options provide to best suit the custom PCB’s intended application.

AdvancedPCB custom PCB surface finish options include the following:

- Leaded & Lead Free (HASL)

- Electroless Nickel Immersion Gold (ENIG)

- Electrolytic Nickel & Hard Gold Plating

- Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

- Immersion Silver & Immersion Tin

- Plated Nickel

- Fused Tin Lead

- Electroless Nickel

- Soft Bondable Gold

Advanced Manufacturing Certifications & Qualifications for Custom PCB Design Requirements

Stringent quality standards and the ability to meet certain certifications may be required for some custom PCB projects, especially those designed for use in military, aerospace, and commercial applications. AdvancedPCB's Standard & Custom Spec PCB manufacturing options both meet IPC-A600 Class 2 requirements at a minimum, which is trusted for dedicated service electronics requiring high performance and extended life. Additionally, advanced certifications are available and include the following:

- IPC 6012 CLASS 3/3A

- AS9100D

- ISO 9001:2015

- MIL-PRF-31032

- MIL-PRF-55110

- ITAR Registered Facilities

- UL Certification for USA/Canada

Other Custom PCB Features & Capabilities for Advanced Designs

Finding a custom PCB manufacturer that can provide advanced fabrication with quickturn capabilities and has a reputation for high quality precision work is key. AdvancedPCB's expanded PCB fabrication capabilities can help you meet all of your custom PCB requirements.

Other design features may include the following with AdvancedPCB's Custom Spec option:

- Castellated Holes

- Controlled Dielectric

- Controlled Impedance

- Counter Sinks

- Counter Bores

- Mask Plugged

- Etch Back

- Tetra Etch

- Cover Coat

- Cavity Process

- Laser Rout

- LPI Legend

- Edge Mill

- Back Drilling

- Controlled Depth Drill

For a full list of AdvancedPCB's custom PCB manufacturing capabilities, download our PDF below or click here to contact your Sales Representative with any questions.

AdvancedPCB

Related Posts