Multilayer PCB Manufacturing – Up to 40 Layers

AdvancedPCB offers a wide range of advanced printed circuit board (PCB) manufacturing capabilities stocks a large variety of laminates for many different applications. From the simplest 2 layer board to the most advanced design with rigorous requirements, engineers and buyers can trust AdvancedPCB to deliver high quality boards, on-time, and with outstanding support.

Expanded Capabilities Include Multilayer PCBs Up to 40 Layers

AdvancedPCB is able to meet the demand for the increased layer count of conventional circuit boards. Multilayer PCB designs allow the engineer to create more powerful boards while at the same time shrink the overall size of the PCB. To meet the demand for higher layer counts and more advanced PCB technologies, AdvancedPCB has invested heavily in strategic acquisitions and in state-of-the-art equipment which has allowed the company to offer the medical, aerospace and defense, industrial, and many other industries advanced PCB capabilities to meet their needs.

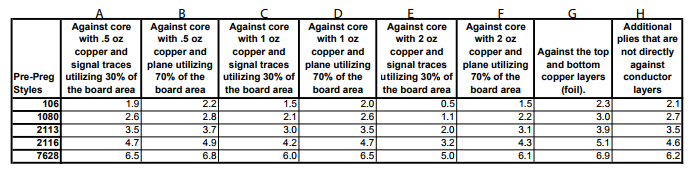

Prepreg Thickness Chart for Multilayer PCB Lamination

Prepreg is the material used in the multilayer PCB lamination process – a woven glass cloth with epoxy resin.

The chart below provides the thickness for a single ply (sheet) of each style of Pre-Preg after processing. These are grouped by the weight and type of the internal conductor layer (typical signal and plane layers) that they will be adjacent to (columns A-F). Those that are adjacent to the top and bottom copper layers will use the column designated for these (column G) regardless of the layer type. All plies that are not directly against a conductor layer (use for situations with more than 2 plies in an opening) will use the additional plies values (column H). These values are based on a minimum of 2 plies of pre-preg per opening between foil and cores or between cores.

This thickness guide is provided as a guide only. The actual thickness will be affected by the copper distribution within the design as well as within the production panels.

Other Advanced Capabilities

- Multilayer RF Designs Up to 8 Layers

- Heavy Copper Up to 20 oz.

- Oversized Boards Up to 37″ x 120″

- Laser Direct Imaging (LDI)

- Laser Drilled Microvias (HDI)

- Stacked Microvias

- Cavity Boards

- Via-in-Pad

- Air Pockets Between Layers

- Blind & Buried Vias

- Buried Chip Resistors

- .00275″ Trace/Space

- Down to .3mm Pitch

- Laminate options for high temp., low loss and lead-free materials

AdvancedPCB

Related Posts

Bridging the Gap: Why Designer-Fabricator Collaboration Matters in PCB Manufacturing

Navigating the Ever-Changing World of PCB Manufacturing: What Designers and Engineers Need to Know