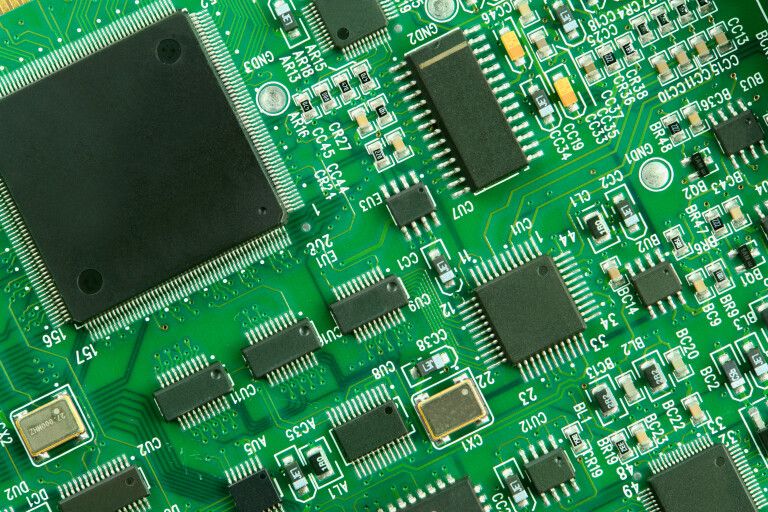

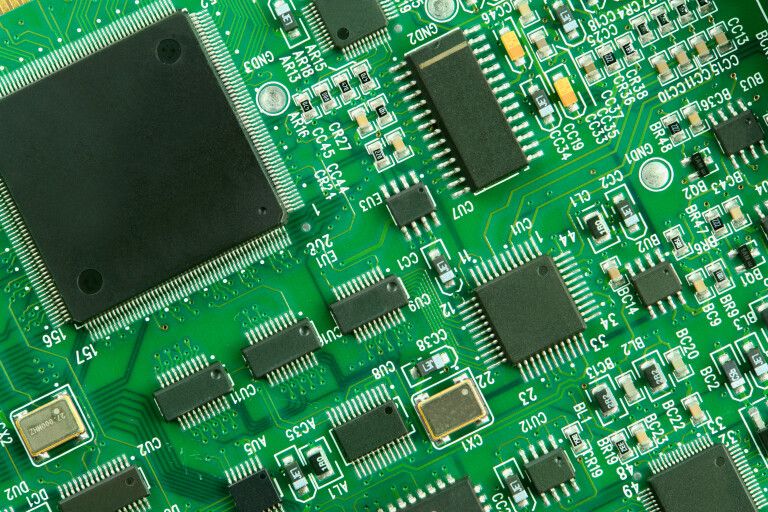

What is Surface Mount Technology?

Surface Mount Technology (SMT) is the widely-used alternative to older through-hole (TH) printed circuit board design and manufacturing practices. While TH fabrication still has its place, SMT has largely taken over where size, weight, and automated manufacturing processes are considerations.

SMT incorporates the use of surface mount devices (SMDs) that replace larger, heavier, and more cumbersome counterparts used in through-hole PCB construction. Today an increasing majority of PCB devices are available as SMDs or packages, making the adoption of SMT board designs and manufacturing practical and cost-effective.

Surface Mount Technology has facilitated the application of electronics for functions that were not practical or even possible with older through-hole fabrication techniques.

SMT Assembly Considerations

Due to the very nature of SMT board construction and smaller, lighter components, automation of PCB construction is facilitated and becomes very efficient for manufacturing, especially for mass production. To gain the most significant advantage in fabrication, SMT construction must be as highly mechanized as possible.

Assembly advantages in SMT manufacturing are numerous:

- Hole drilling is nearly or totally eliminated, with the SMDs being connected directly to the board surface.

- Reliability is enhanced, since there is no requirement to fit component leads through holes for subsequent soldering in place. Soldering SMDs to surface pads is simpler and faster, reducing assembly time while also improving quality.

- Through-hole fabrication required careful alignment with drilled holes, and often pre-forming of the leads to accommodate specific PCB layout and component placement. SMT assembly eliminates the majority of SMD placement intervention, allowing for more automation and thereby reduced cost. SMDs have smaller leads, or may have none at all.

- SMT assembly is highly automated, speeding production and reducing turn-around for customers.

Discover AdvancedPCB SMT & Full Range of Capabilities

How Does SMT Assembly Work?

In a simplified view of SMT manufacturing, fabrication generally consists of several highly-automated processes:

- Board material contains solder pads without holes, to which solder paste is applied with a screen-printing-like process. Solder placement can be controlled through the use of a precise stencil template for the individual PCB being fabricated, to apply the material only where needed.

- Automated component picking and placement machines then position the desired SMDs and other components on the boards precisely, often fed to the machines on reels or tapes, or delivered in static-free media, in the case of components such as integrated circuits.

- Boards then continue to soldering operations (ovens) which heat the solder pads to the point where the applied solder paste melts and bonds the components to the board.

- When both sides of the board are being utilized for components, the placement/soldering processes are repeated for the reverse side.

- Where heat-sensitive components are incorporated on the PCB, these may be installed after the automated soldering, either manually or through processes that would not damage the component.

- Boards are subsequently “washed” to remove excess flux or solder residues that could cause shorting of components due to their extremely close placement tolerance.

- Finished, cleaned, and dried products are then ready for final inspection of quality including missing components, alignment issues, or soldering issues that could generate potential problems.

- Inspections of SMT boards can also be automated. Equipment is available that retains a visual image of the correct board construction, and compares the boards produced to the reference image. Deviations can then be brought to the attention of the machine operator for action or more detailed manual inspections.

- Inspected boards then proceed to any required testing of circuits and functionality.

Take Advantage of AdvancedPCB's Quick Turnaround Services

Other SMT Fabrication Considerations

SMT manufacturing offers maximum flexibility in building printed circuit boards:

- Increased automation

- Improved reliability and performance

- Reduced manual intervention for component placement

- Nearly total elimination of hole drilling operations

- Smaller, lighter boards

- Ease of assembly, using both sides of the board without the hole limitations that exist in through-hole construction

- Ability to co-exist with through-hole components, even on the same board

- Increased density – more SMD components in the same space, or the same number of components in a much smaller footprint.

Highly-automated SMT assembly equipment can fabricate PCBs very efficiently, while maintaining reliability and quality. Machines today are capable of placing components at a rate of 25,000 per hour or more.

With the many advantages provided by SMT construction and assembly processes, the highly-specialized manufacturing equipment required for fabrication can be cost-prohibitive to many companies. This is why many companies that design SMT PCBs rely on third-party specialized resources for actual manufacturing of the boards they have designed.

AdvancedPCB

Related Posts

Future trends of the circuit board

Understanding the Difference between PCB prototyping and Full Spec Production