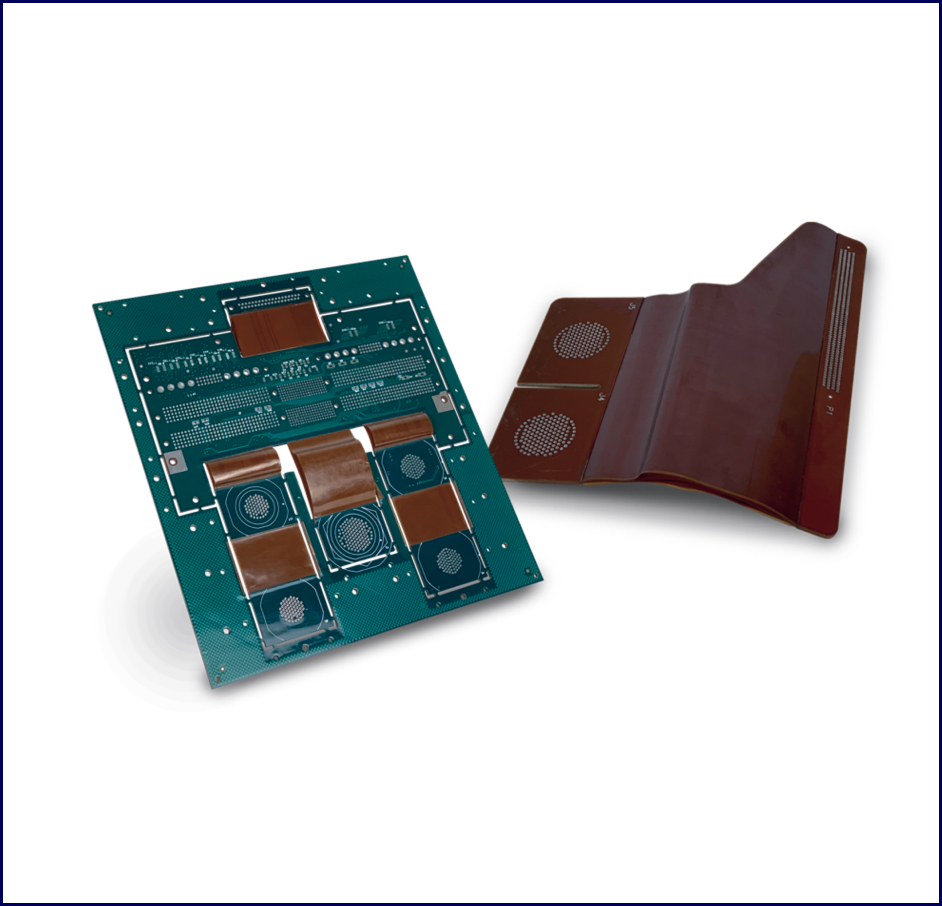

Flex & Rigid-Flex PCBs

Two major trends in electronics are a rising number of products that talk to one another and ever-shrinking product sizes. Not surprisingly, products that use RF technology also are using rigid flex circuitry. Some of the benefits of Flex and Rigid-Flex include:

- Weight and space reduction

- Meets dynamic flexing requirements

- Improve aesthetics and reliability

- Eliminate connectors

- Supply thermal management

Flex & Rigid Flex Tech Highlights

- IPC 6013 type 4 class 3 & (S) for space for high reliability commercial and military

- Flex Layer Counts from 1 - 12+ layers

- Rigid Flex Layer Counts from 4 - 26+ layers

- Standard Panel sizes up to 18 x 24 Specialty sizes 24 x 28+ as needed

- Back Drill Depth Tolerances from 0.005" down to 0.002"

- Full engineering DFM support

- Bookbinder construction capability

- Silver shielding and hybrid materials capability

Flex & Rigid Flex Design Challenges

Included with the purchase of our Flex and Rigid-Flex PCBs is DFM support from our team of expert engineers. They review each of our flexible printed circuit board designs prior to production to ensure the design is robust for fabrication. They’ll also work directly with your in-house engineering team to ensure you have complete support for your project. From a design standpoint, that drives a spate of challenges in the stackup. AdvancedPCB can help avoid common issues as:

- Placing vias outside the stiffener area, which can cause via cracking

- Designing bend areas that may stress component solder joints

- Not providing the proper stiffener information

- Potential signal integrity (SI) issues and solutions of a design that bends

- Placing the edge of the feature closer than .010 mm to the edge of the board

Flex and Rigid-Flex Offerings

AdvancedPCB offers the following matrix for Flex and Rigid-Flex technology:

- Green

- Flex boards with layer counts of 2-6 layers

- Rigid-Flex boards with layer counts of 4-14 layers

- Yellow

- Flex boards with layer counts of 8-10 layers

- Rigid-Flex boards with layer counts of 16-24 layers

- Red

- Flex boards with layer counts of 12+ layers

- Rigid-Flex boards with layer counts of 26+ layers

Additionally, we offer the necessary certifications for orders for the Defense and Aerospace industries as well as Commercial industries including:

- ISO 9001 Certified

- AS9100D Certified

- MIL-PRF-31032 Certified (MIL-P-55110 Certified)

- MIL-P-50884 Certified

- ITAR Registered at all sites

- IPC 6012 Class 3 & 3S

- IPC 6013 Class 3 & 3S

- IPC 1791 Trusted Electronics Qualified Manufacturers Listing (QML)

Flex and Rigid-Flex Quick-Turn Availability

With recent investments in new manufacturing equipment and high-end personnel, AdvancedPCB has the capabilities to offer quick-turn production for Rigid-Flex products.

| AdvancedPCB Flex and Rigid-Flex Quick-Turn Schedule | ||

|---|---|---|

Flex or Rigid-Flex | Layer Count | Quick-turn time |

| Flex With Stiffener | 1-2 | 5, 7, 10, 15-day options |

| Flex With Stiffener | 4-6 | 7, 10, 15-day options |

| Rigid-Flex | 4-6 | 7, 10, 15-day options |

| Rigid-Flex | 8-12 | 7, 10, 15-day options |

| Rigid-Flex | 14-16 | 10, 15-day options |

| Rigid-Flex | 18-22 | 15-day option |

| 2X Lam Cycle Rigid Flex HD | N/A | 20+ day option |

*Note: All materials used are UL certified; Specific APCT UL Certification in process.