Standard Technology PCBs

An industry leader for more than a quarter century, AdvancedPCB has earned the trust and loyalty of our partners because of our consistent and reliable execution of quick-turn orders. We offer two standard PCB specs: standard and advanced.

Standard PCBs are basic FR4 boards with a 0- to 12-layer count and a lead-free HAL plating finish. Quantity doesn’t matter; we will make as few as one PCB or as many as 10,000 without compromising the quality. All standard PCBs orders undergo the same rigorous fabrication and quality check process: standard PCBs are inspected according to IPC Class 2 Standards.

The benefits of standard PCBs include:

- No tooling NRE charges

- No tooling NRE charges when upgrading from standard PCB to advanced PCB

- There is a one-time electrical test charge even for a fixture when upgrading to advanced PCBs

Specifications | Standard Specs |

|---|---|

Layer Count | 0 - 12 Layers |

| Turn Time | Same Day - 5 Day |

| Quantity Req. | 1 - 10000+ |

| Materials | FR-4 |

| Plate Finish | Lead-Free HAL* |

| Cert. / Qualifications | IPC Class 2 - A600 |

| Board Thickness | .031" / .062" / .093" / .125" |

| Copper Weight | 1 oz. Inner / Up to 2 oz. Outer |

| Trace / Space | 5 / 5 Mils |

Standard vs. Advanced

Whether you need a double-sided or a multilayer PCB, AdvancedPCB is your one-stop printed circuit board provider. When deciding whether you need a standard PCB or an advanced PCB, start by looking at the specs.

Specifications | Standard | Custom |

|---|---|---|

Layer Count | 0 - 12 Layers | 0 - 40 Layers |

Turn Time | Same Day - 5 Day | Same Day - 4 Weeks |

Quantity Req. | 1 - 10000+ | 1 - 10000+ |

Materials | FR-4 | FR-4/Rogers/Polyimide/Aluminum Clad/High-Temp. FR4/Others » |

Plate Finish | Lead-Free HAL* | Electrolytic Hard Gold/Soft Gold/ENIG/Nickel/Immersion Silver OSP/Leaded & Lead-Free HAL |

Cert. / Qualifications | IPC Class 2 - A600 | IPC6012 Class 2-3A / IPC6018 Class 3 MIL-PRF-31032 / MIL-PRF-55110 / ISO 9001:2008 / AS9100C / More » |

Board Thickness | .031" / .062" / .093" / .125" | Full Range Available |

Copper Weight | 1 oz. Inner / Up to 2 oz. Outer | 0.5 - 4 oz. Inner / 1 - 20 oz. Outer |

Trace/Space | 5 / 5 Mils | Down to 2.75 / 3 Mils |

Solder Mask (LPI) | Green | Various Color Options |

Legend | White | Various Color Options |

Min. Hole Size | 0.010" | 0.004" |

Hole Tolerance | +/- 0.005" | +/- 0.003" (Upon Request) |

Rout Tolerance | +/- 0.010" | +/- 0.005" (Upon Request) |

Slots/Cutouts/Edges | Non-Plated Only | Plated / Non-Plated |

Plated Holes | Plated / Non-Plated | Plated / Non-Plated |

UL Markings/Dates | Yes** | Yes** |

Lead-Free Markings | Yes | Yes |

Gold Fingers | Yes | Yes |

Fiducials | Yes | Yes |

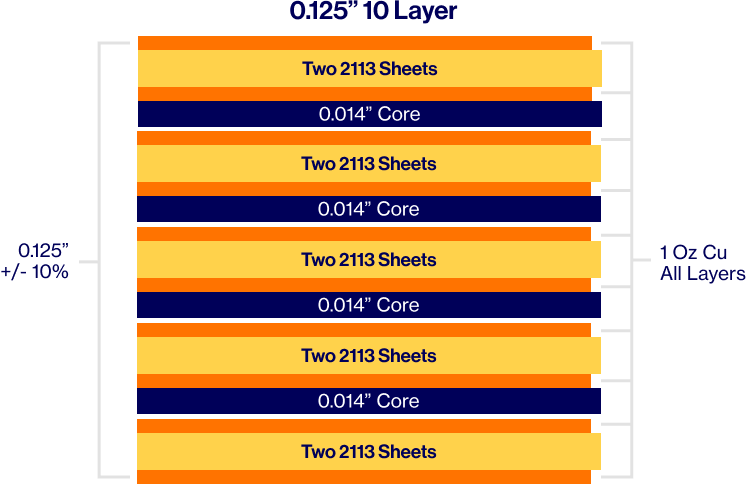

Scoring | Yes | Yes |

ITAR | Yes | Yes |

Castellated Holes | X | Yes |

Controlled Dielectric | X | Yes |

Controlled Impedance | X | Yes |

Counter Sinks | X | Yes |

Counter Bores | X | Yes |

Blind/Buried Vias | X | Yes |

Microvias | X | Yes |

Mask Plugged Vias | X | Yes |

Via-in-Pad | X | Yes |

Etch Back | X | Yes |

Tetra Etch | X | Yes |

Cover Coat | X | Yes |

Cavity Process | X | Yes |

Laser Rout | X | Yes |

LPI Legend | X | Yes |

Edge Mill | X | Yes |

Unique Serialization | X | Yes |

Back Drilling | X | Yes |

Controlled Depth Drill | X | Yes |

* Standard Spec pricing assumes lead-free HAL. Alternatively, board finish may be upgraded to ENIG or Silver at no additional cost in the rare event lead-free HAL becomes temporarily unavailable.

** Added markings contingent on available space on boards. 94V-0 may be added upon request at the time of order entry or if noted in files.

Please Note: Holes will be plated if no specifications provided. Default Solder Mask color is Green unless another color option is requested. Default Legend (Silkscreen) color is White unless another color option is requested.

Still wondering whether or not your board is a Standard or Advanced PCB?

If you are still debating standard vs. advanced PCB, keep in mind what you ultimately need your board to do. When you design your PCBs you can use our free DFM file check system to avoid CAM holds. You can also find a full list of capabilities online to help inform your decision.

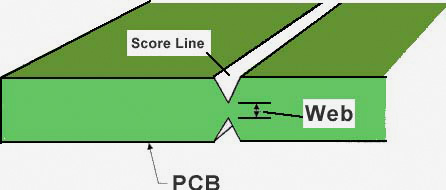

Build Your Prototype

Eliminate the hassle of order minimums and lengthy production times. Whether you’re building a proof-of-concept, working prototype, visual model, or fully functional prototype, proceed with confidence knowing that will receive a buildout of a single board in just days:

- Get started with our free PCB Artist software.

- Upload Gerber files and have them analyzed and corrected with our FreeDFM evaluation software to begin our CAM engineer evaluations.

- After the design is approved, order as few or as many boards as you would like in a time frame of your choosing.

Standard PCB: Laminates

Selecting the right laminate for your PCBs is an important part of the design process. The laminate will help achieve final thickness and give you a PCB that you can use for your application. All standard PCBs employ the common FR4 laminate material.

Laminate | Type | Tg Celsius | Td Celsius | T-260 Minutes | T-288 Minutes | Dk | Df | UL94 |

|---|---|---|---|---|---|---|---|---|

Aluminum Clad | @ 1 MHz | @ 1 MHz | ||||||

130 | 380 | 4.8 | 0.016 | V0 | ||||

Isola | @ 1 GHz | @ 1 GHz | ||||||

FR4 / Phenolic | 180 | 340 | 60 | 30 | 4.04 @ 2 GHz | 0.021 @ 2 GHz | V0 | |

FR4 / Phenolic | 180 | 340 | 60 | >15 | 4.01 @ 2 GHz | 0.0200 @ 2 GHz | V0 | |

FR4 | 135 | 10 | 4.34 | 0.016 | V0 | |||

FR4 High Temp | 170 | 300 | 10 | >2 | 3.95 | 0.0161 | V0 | |

FR4 | 190 | 360 | 60 | >30 | 3.69 | 0.0091 | V0 | |

Modified Epoxy | 225 | 364 | 60 | >20 | 3.58 | 0.0059 | V0 | |

Polyimide | 260 | 416 | 60 | 60 | 3.78 | 0.0172 | HB | |

Polyimide | 260 | 396 | 60 | 60 | 3.78 | 0.0172 | V0 | |

Nelco | 1 GHz | 2.5 GHz | ||||||

FR4 High Temp | 175 | 325 | 4-8 | 4.0 @ 2.5 GHz | 0.022 | V0 | ||

Modified Epoxy | 175 | 345 | 30 | 4.1 | 0.02 | V0 | ||

N4000-12 | Modified Epoxy | 190 | 350 | >60 | 3.7 | 0.008 | V0 | |

N4000-13 | Modified Epoxy | 210 - 240 | 350 | >30 | >10 | 3.7 | 0.009 | V0 |

N4000-6 SI/EP | Modified Epoxy | 210 - 240 | 350 | >30 | >10 | 3.7 | 0.009 | V0 |

N4000-29 | FR4 High Temp | 175 - 185 | 350 | >60 | 15 | 4.3 | 0.015 | V0 |

Arlon | 1 MHz | 1 MHz | ||||||

Cer/Glass | 250 | 407 | >60 | >60 | 4.2 | 0.01 | HB | |

Rogers | 8-40 GHz | 10 GHz | ||||||

PTFE / Glass | 500 | 2.2 | 0.0009 | V0 | ||||

PTFE / Microfiber | 500 | 2.33 | 0.0012 | V0 | ||||

Cer/PTFE | 500 | 2.94 | 0.0012 | V0 | ||||

Cer/PTFE | 500 | 6.45 | 0.0027 @ 10 GHz/A | V0 | ||||

Cer/PTFE | 500 | 10.7 | 0.0023 @ 10 GHz/A | V0 | ||||

Cer/PTFE | 500 | 3 | 0.001 | V0 | ||||

Cer/PTFE | 500 | 6.5 | 0.002 | V0 | ||||

Cer/PTFE | 500 | 11.2 | 0.0022 | V0 | ||||

Cer/PTFE | 500 | 3.02 | 0.0016 | V0 | ||||

Cer/PTFE | 500 | 10.8 | 0.0027 | V0 | ||||

Hydrocarbon/Cer | >280 | 425 | 3.55 | 0.0027 | N/A | |||

Hydrocarbon/Cer | >280 | 390 | 3.66 | 0.0037 | V0 | |||

Hydrocarbon/Cer | >280 | 390 | 3.3 ± 0.05 @ 10 GHz | 0.004 | V0 | |||

Taconic | 10 GHz | 10 GHz | ||||||

PTFE / Glass | 3.2 | 0.003 | V0 | |||||

PTFE / Glass | 2.95 | 0.0028 | V0 | |||||

PTFE / Glass | 2.5 @ 1 MHz | 0.0006 @ 1 MHz | V0 | |||||

PTFE / Glass | 553 | 2.55 | 0.0012 @ 1.9 GHz | V0 |

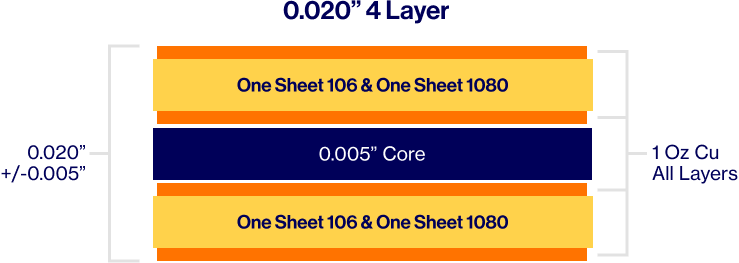

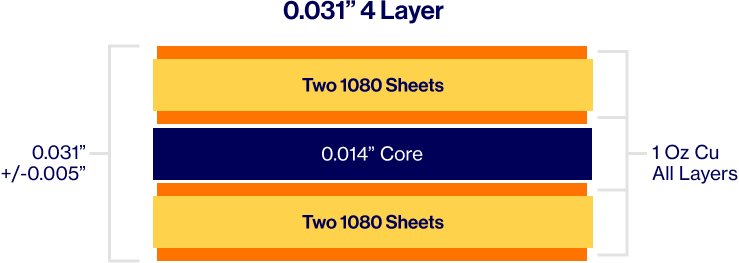

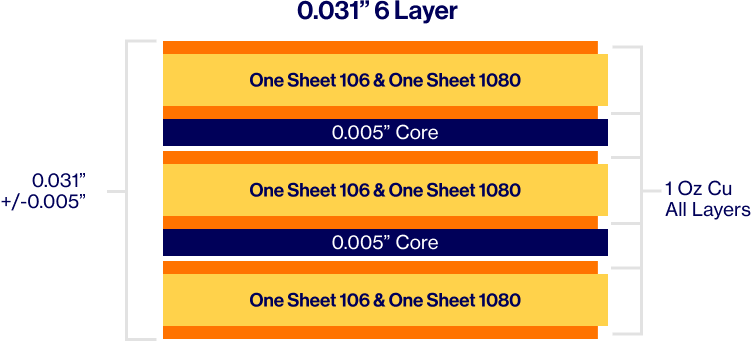

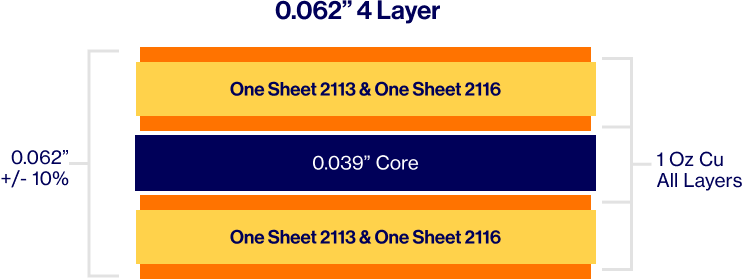

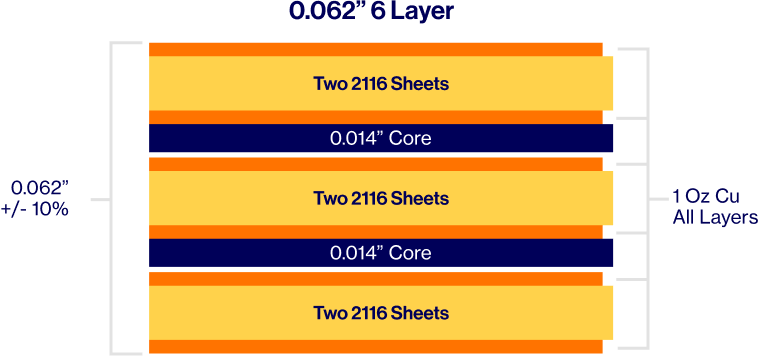

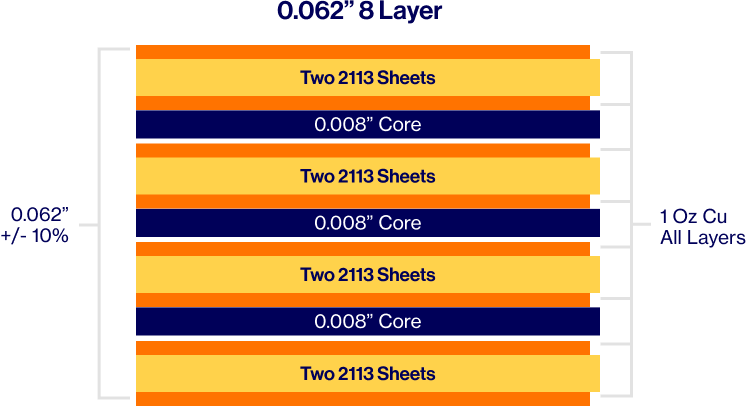

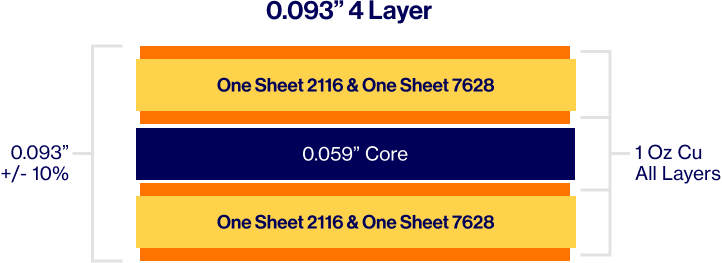

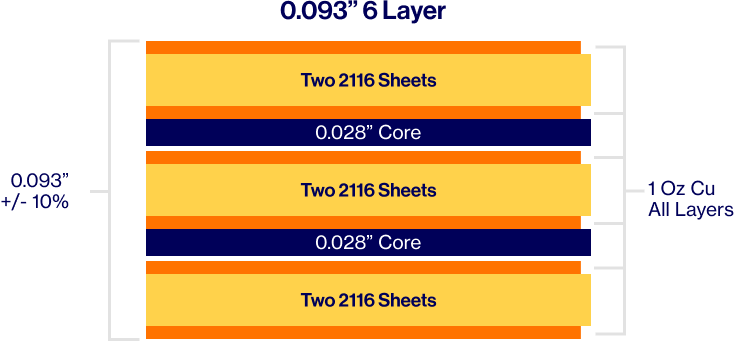

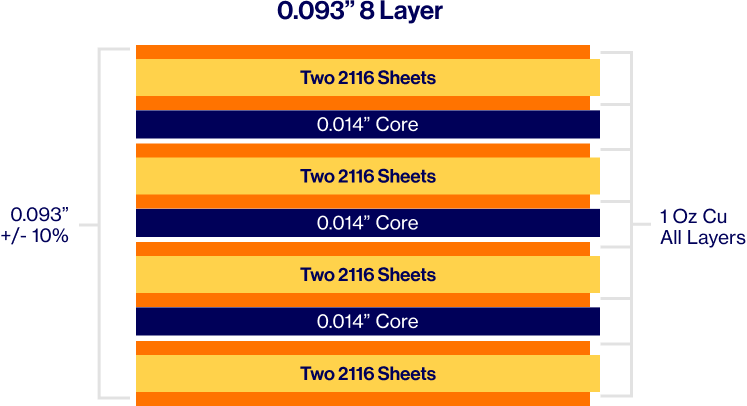

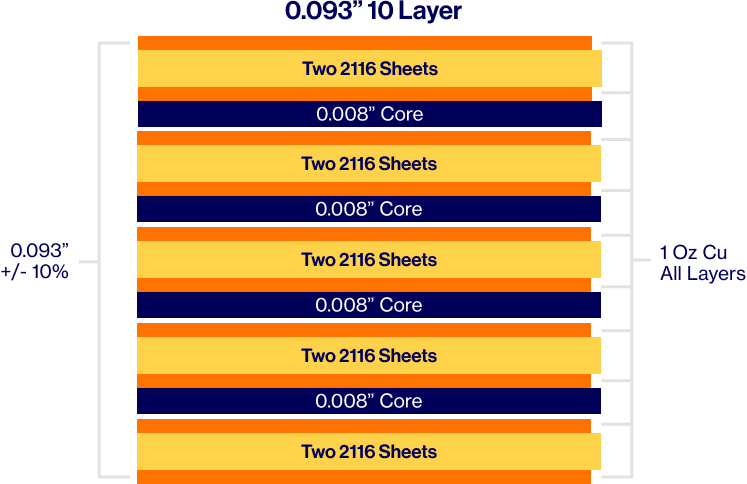

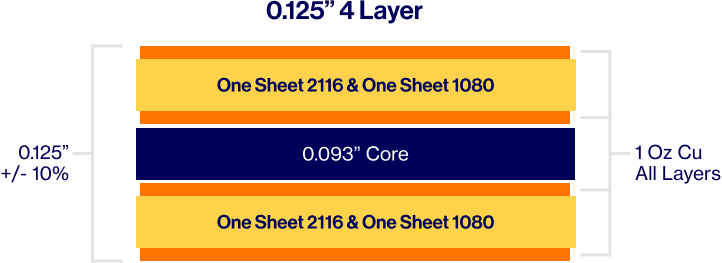

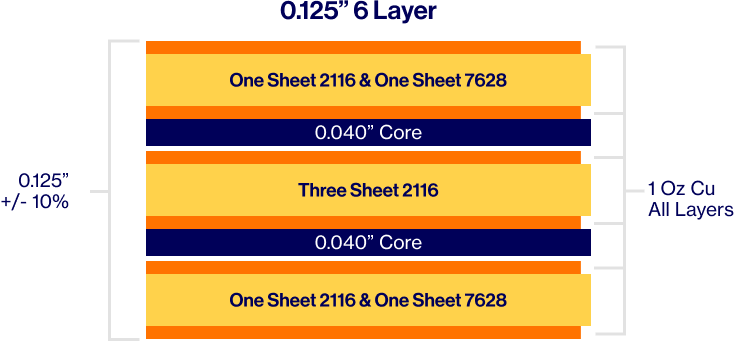

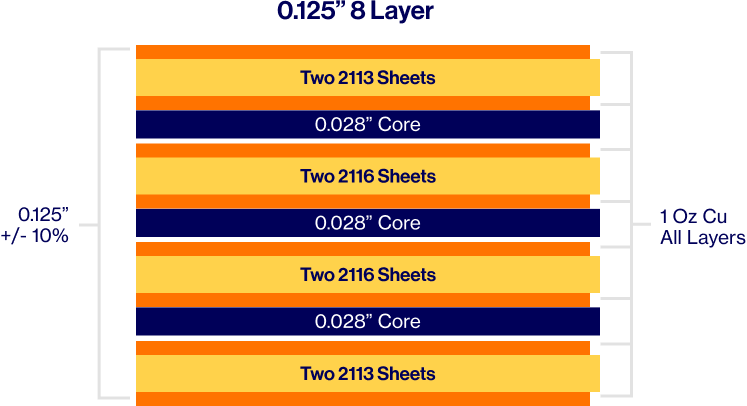

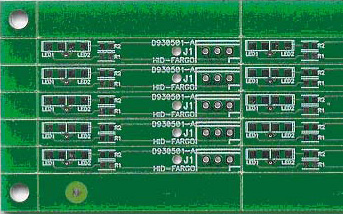

Standard PCB: Multi-layer Stackup

Typical PCB stackups for specified layer count and finished thickness for 1 oz copper layer* | ||||

|---|---|---|---|---|

4-layer | 6-layer | 8-layer | 10-layer | |

0.020" | ||||

0.031" | ||||

0.062" | ||||

0.093" | ||||

0.125" | ||||

Max board size | 16" x 22" | 16” x 22” | 16” x 22” | 14” x 20" |

Standard PCB: Board Finish

It’s important to have the PCBs finished to ensure a consistent surface for connecting components to the boards and to protect against decay. Standard PCBs provide you with UL-approved circuit boards with a tin copper alloy lead-free solder finish that meets the requirements of RoHS, REACH and Conflict Metals regulations.

Electrical Test

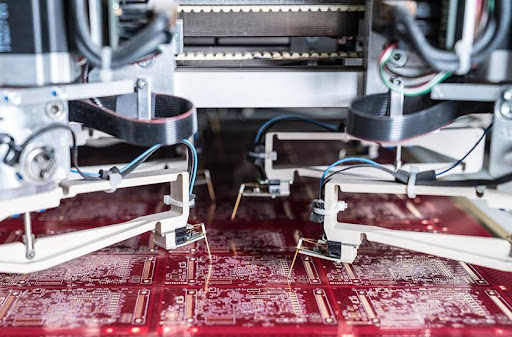

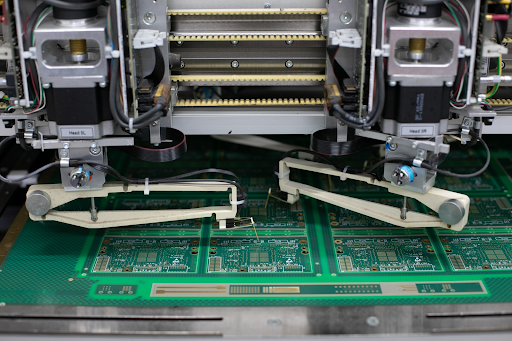

We use two types of testing equipment on your circuit boards:

- Fixtureless: Flying probe with Everett Charles ATG test machines

- Fixture-based: Universal grid testing

Flying Probe Testing

Flying Probe Testing Universal Grid Testing

Universal Grid Testing