VMI Kanban

Stock Management

Effective inventory management is crucial to avoid cash flow issues caused by excessive stock sitting on shelves. AdvancedPCB offers solutions to optimize your inventory, providing buying leverage, rapid ramp-up capabilities, and scalable flexibility. This approach not only saves significant cash flow but also reduces physical space requirements, enabling efficient assembly.

How Our Stocking Programs Operate

At AdvancedPCB, our stocking programs operate with flexibility. You can store products in our distribution center, consign them to your warehouse, or utilize a conveniently located bonded warehouse. Tailored solutions are also available, meeting your specific requirements.

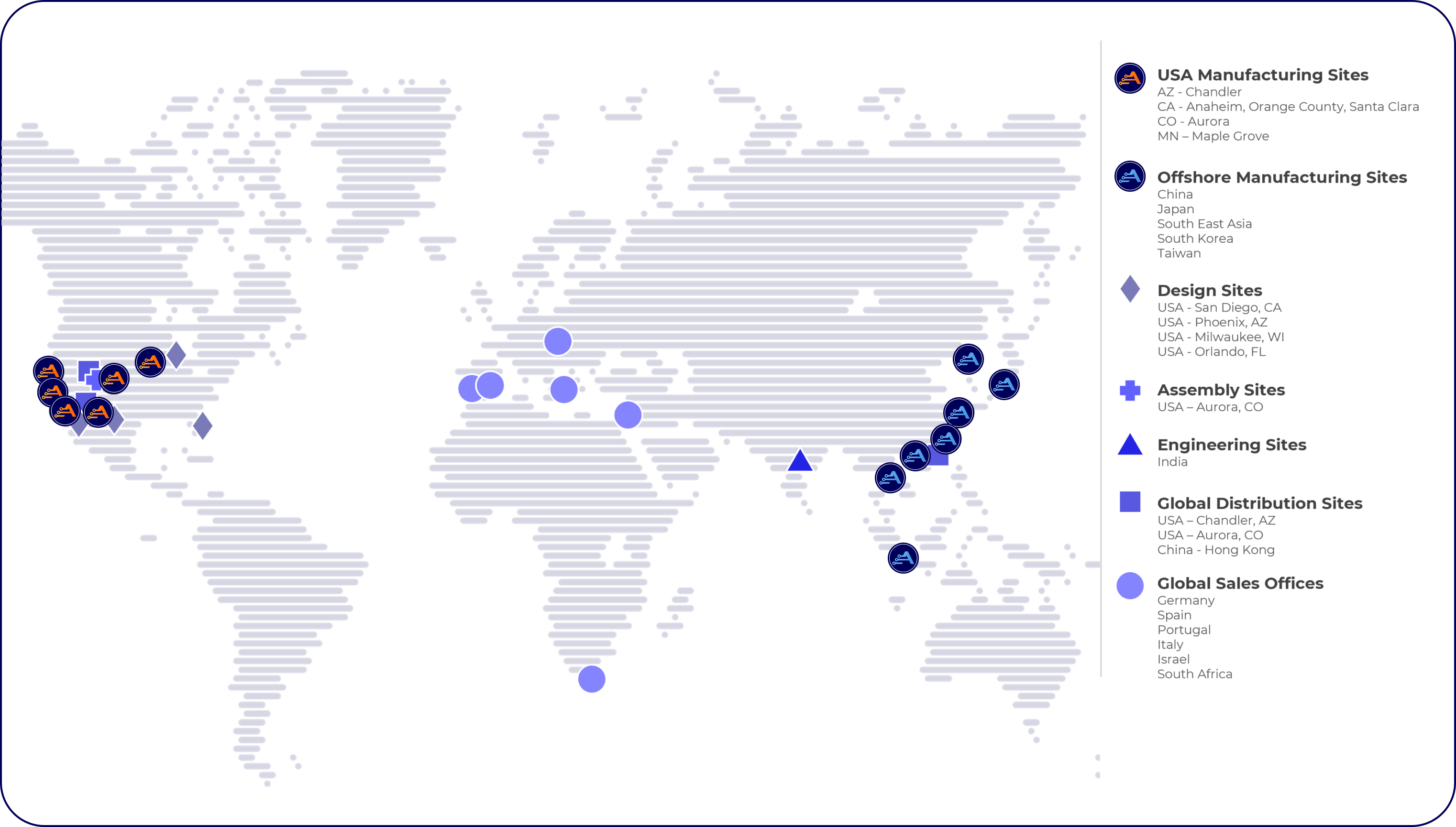

We schedule drop shipments of your inventory and maintain a predetermined minimum stock level from which products are released for production and replenished as needed. Our multiple locations ensure prompt shipping to your destination, and we efficiently manage Vendor Managed Inventory (VMI) and Kanban programs.

We schedule drop shipments of your inventory and maintain a predetermined minimum stock level from which products are released for production and replenished as needed. Our multiple locations ensure prompt shipping to your destination, and we efficiently manage Vendor Managed Inventory (VMI) and Kanban programs.